Cloud

Application

Hosting

Contact

Us

Cloud

Application

Hosting

Application

Development

Mobile

Applications

Data

Interfaces

Enterprise Data

Visualization &

Analysis

Incident

Management

Risk

Assessment

Risk

Management

Suite

The Zoldak Group

Workers

Compensation

Process Risk

Management

Risk Management Technologies

Developed by ZGi

© 2014 The Zoldak Group, Inc.

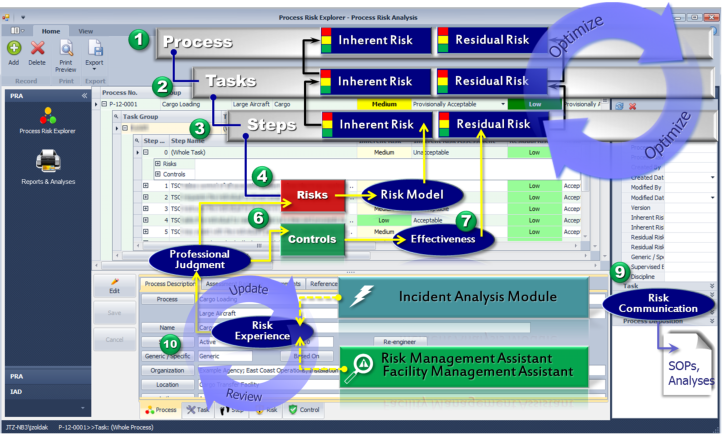

The RMS Process Risk Management Module (PRM) identifies and addresses specific risks associated with

simple to complex processes by via a systematic documentation and optimization methodology. The

goal is to reduce risk to employees, mission, infrastructure, stakeholders, etc. to as low as reasonably

achievable while providing opportunities to refine and improve the process continually. This

methodology works for any process and discipline. Furthermore, it documents and incorporates multi-

disciplinary inspired, continual improvement and risk management principles into the overall process.

PRA Supports Critical Infrastructure Protection Programs: This type of optimization is vital to general

risk management activities conducted by agencies and the private sector. It has great application for

critical infrastructure risk management in the chemical, commercial, manufacturing, dams, emergency

services, nuclear, agriculture and food, communications, defence industrial base, information

technology, national monuments, postal and shipping, health care/public health, transportation, and

water sectors.

This flexible PRM methodology is summarized as follows:

1.

Process: A process is an organized, series of human and automated tasks, and task steps that

brings about some result. This result includes physical / non-physical product, repair,

maintenance, operation, surveillance, monitoring, etc.

2.

Tasks: Processes are documented and broken down into standard or non-standard tasks.

3.

Steps: Each task is documented and sub-divided into one or more steps

Steps are documented. Steps are sequential and may branch based on various conditions. Step

documentation include methods, agents, raw materials, required training, and much more.

4.

Inherent Risk Assessment: Next, each inherent risk is identified and characterized at the step

level by considering all components of the process systematically. Risks are assessed using a risk

model, professional judgement or both.

An algorithm aggregates the overall inherent risk at the task and overall process level providing a

detailed profile of inherent risk.

The accuracy of inherent risk assessments of existing processes increases when validated by data

from the Incident Analysis Module (actual incidents with severity) and the Risk Management

Assistant (potential risks assessed though inspections or audits).

Inherent risk characterization is an art and science and sometimes proceeds in a circular process

until the team feels that X% of the process risk is characterized. Additional risks may be added at

any time in this ongoing, evolving process.

5.

Re-Engineering: The next step in the PRM process is to review the process and identify re-

engineering opportunities to improve efficiency, reduce waste, reduce risk to process completion,

and reduce risk to individuals, infrastructure, and mission. This comprehensive re-engineering

approach is improved when done collaboratively with process owners, process operators,

engineers, scientists, supervision, management, security, facility managers, subject matter

experts, and others.

6.

Controls or Countermeasures: After all re-engineering opportunities are initially identified and

addressed, further risk reduction is achieved by applying risk controls or countermeasures.

Controls include from personal protective equipment, supervision, training, medical

surveillance, work methods, surveillance, administrative controls, engineering controls, and

more. PRM includes an extensive control library to get started.

7.

Residual Risk Calculation: Next, the overall control / countermeasure risk-reduction efficacy is

assessed as the residual risk which is rolled up from steps to the entire process via an algorithm.

8.

Overall Process Risk Assessment: A final assessment is performed after the calculation of the

residual risks. This is the overall risk assessment that indicates if the current risk level is

acceptable or if further optimization is needed to achieve risk reduction goals.

9.

Standard Operating Procedures: The PRM generates a risk-based Standard Operating Procedure

and other process documentation that is important for training and supervision.

10.

Continual Surveillance and Optimization: The process is continued to be followed after the

implementation of a the risk-based SOP though the analyses of incidents and inspections. The

PRM is integrated with the ZGi Incident Analysis Module, Facility Management Assistant, and Risk

Management Assistant so that it is possible to identify the effectiveness of re-engineering and

risk controls. This analysis may identify locations or conditions where the controls need to be

refined. The PRM provides tools for creating a new version of the primary process and apply re-

engineering that addresses local, time, demand, and other variations.

RMS Process Risk Management and Analysis Module