Cloud

Application

Hosting

Contact

Us

Cloud

Application

Hosting

Application

Development

Mobile

Applications

Data

Interfaces

Enterprise Data

Visualization &

Analysis

Incident

Management

Risk

Assessment

Workers

Compensation

Risk

Management

Suite

The Zoldak Group

Process Risk

Management

Risk Management Technologies

Developed by ZGi

© 2025 The Zoldak Group, Inc.

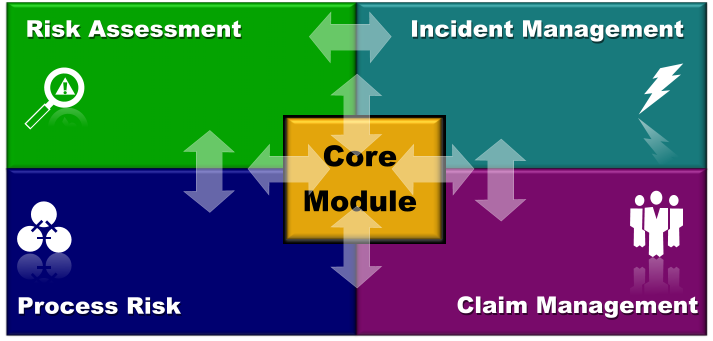

The Risk Management Suite (RMS) is a Commercial Off-The-Shelf (COTS) product composed of a

comprehensive set of proven, integrated, scalable enterprise-level risk management modules. The RMS

is comprehensive because it consolidates the risk management process across discipline, from multiple

sources, and provides enterprise management with a decision support tool and support to specific

organizational requirements. There are four major integrated RMS modules with a common core module

providing security, data leveraging, connectivity, and analysis. Major RMS modules include:

1.

Incident Analysis and Response (Incident Analysis Module)

2.

Risk Assessment via inspections and audits (Facility Management Assistant & Risk Management

Assistant)

3.

Workers’ Compensation Claims Management (Compensation Management Module)

4.

Process Risk Management (Process Risk Management Module)

The RMS supports all requirements for a Safety Management Information as proscribed in Executive

Order 12196--Occupational safety and health programs for Federal employees while providing

integration with workers’ compensation claims under the Federal Employee Compensation Act (FECA).

Consolidated, Comprehensive, Collaborative Risk Management: The RMS is the only commercial

system to integrate these functional areas while maintaining a collaborative, all-hazard approach to risk

management. The RMS is also unique because it consolidates and integrates enterprise risk

management functions into a single system supporting traditionally non-integrated enterprise

organizations. This provides enterprise management with a current risk profile composed of a range of

risks traditionally managed by separate organizations such as Health and Safety, Industrial Hygiene,

Environmental, Fire Protection, Force Protection, Security, Facility Management, Critical Infrastructure,

and others.

Secure, Segmented User Roles: The RMS segments data by organization. Users are assigned to any level

of the organizational hierarchy for which they have responsibility. User profiles control access to specific

modules, module segments, module functions and discipline views. For example, this unique capability

elegantly integrates traditional safety and claim management roles, leverages common data and

restricting access to other data. These roles are configurable and are be maintained by authorized

system administrators.

Data Roll-Up: Another feature of the RMS architecture is that data are rolled up from a specific physical

location through successive branches of the hierarchy, e.g., location, organization, region, enterprise.

Users are assigned to a specific node of this hierarchy and have access to data from this level and below.

This establishes and enforces a hierarchical review process, improves data quality, enforces

accountability, increases data quality and timeliness, and provides a consistent, validated database that

that support planning initiatives and promotes decision effectiveness. Cost savings are realized through

the establishing and maintaining a single system.

Workers’ Compensation Claims Management (CMM): The CMM supports all claim management

functions required by the Federal Employee’ Compensation Act (FECA). It results in reduced

effort in generating and managing claims, direct claim status and cost updating from the

OWCP, increases filing timeliness, and provides analytical tools to identify and address

opportunities for reducing injury/illness case rates, lost production days, etc. This directly

supports the Federal Workers and Ensuring Reemployment (POWER) Initiative. It also

supports recommendations by the U.S. Government Accountability Office (GAO) report to

Congress that “Better data management strategies would strengthen efforts to prevent and address

improper payments.” (GAO-08-284 and others).

Incident Analysis and Management (IAM): The RMS supports for the investigation of any event that has,

or nearly-has, affected life/health, mission, infrastructure, property/equipment, security,

environment, and more via the Incident Analysis Module (IAM). The IAM features a risk-

based investigation and response methodology and a software application that provides a

consistent system for documenting incidents while providing discipline specificity that

supports a wide range of incidents. This includes injuries, illnesses, near misses, notices of

unsafe-unhealthful conditions, motor vehicle incidents, property damage, security incidents,

environmental incidents, fire, explosions, aircraft incidents, etc. The IAM also supports and All-Hazard

program by addressing risk from a lessons-learned perspective.

The most common focused use for the IAM is to support occupational injury/illness investigation and

recordkeeping as proscribed in the OSHA Recording and Reporting of Occupational Injuries and Illness

standard (29 CFR 1904). The IAM supports and exceeds this requirement and complies with all specific

federal agency and DoD health and safety programs. OSHA recordability is determined by a wizard which

increases accuracy.

A unique feature of the IAM is that it integrates with an existing claims management system or the ZGi

RMS Claims Management Module (below). Our clients who have done this have successfully leveraged

common safety and claims data, reduced effort by creating notifications of claims or accident reports to

each discipline, and by reducing overall injury and illness rates.

Integrated Risk Assessment and Management: Risk assessment and management results in an overall

and detailed characterization of risk sources, potential impacts, severity / probability

estimates, and risk reduction plans. The overall goal is a systematic approach to the

recognition, evaluation, and control of a wide ranges of risks with the potential to interact

propitiously before an affect to human health/safety/security, mission, infrastructure,

equipment, reputation, environment, etc. occurs. Two components of the RMS support this

risk management process:

Facility Management Assistant (FMA): First deployed in 1994 to the intelligence community, the

FMA is focused directly on addressing findings from risk-based inspections and audits. The FMA is

now used by a range of federal, DoD, and other agency clients to support risk management

programs. It has been mentions in agency awards and as a best practice (The Floyd D. Spence

National Defense Authorization Act for Fiscal Year 2001, PL 106-398, Section 1112).

This focus features a risk-management methodology coupled with a software application which

supports quality assurance and risk management and achieves compliance along the way. Note that

most applications are narrowly compliance-driven and focus on a single discipline, e.g., OSHA, EPA,

etc.).

The FMA was specifically designed to extend traditional inspection practices to include continuous

improvement, risk metrics, risk models, Operational Risk Management (ORM) support, All-Hazard

Support, and more. Analytical tools provide the ability to identify a group of findings and address

them collectively. The FMA integrates with work order systems so to reduce the time from

observation to correction and provide a lessons-learned database for training and planning.

The FMA features an easy to use workflow that reduce the time to document and manage a finding.

Tailorable wizards are used to simplify risk assessment process.

Risk Management Assistant (RMA): The risk management approach used in the FMA is extended in

the RMA to include the documentation and evaluation of a wide range of conditions from a risk

potential. FMA and RMA both support enterprise risk assessment and management, RMA extends

FMA functionality by supporting multi-disciplinary inspections, audits, and conditions assessments.

It documents specific conditions establishing a risk-assessed database of processes, agents, indoor

air quality, environmental monitoring, controls, etc. Findings are generated when any of these

conditions require attention. Findings are generated in two ways: via modifiable electronic

checklists (yes/no, performance) or direct observation. The management of the findings is

performed using the familiar FMA methodology.

Process Risk Management (PRM): The Process Risk Management Module (PRM) establishes a

collaborative environment for optimizing risk of current or proposed processes. Processes

include a range of human and/or automated activities. Processes are documented as tasks

and task steps. An inherent risk is formulated as a baseline function and residual risk is

determined following re-engineering and controlling identified risks. This methodology

features a continuous improvement, optimization approach. This approach is also proactive

and responsive to process changes (location, demand, agents, materials, tools, technology, etc.) and to

evidence through incident analysis and risk assessments (inspections and audits). We refer to this as

evidenced based risk assessment. Inspectors and investigators use risk-optimized process SOPs to

determine if any deviations in the SOP occurred leading to an incident or an risky condition.

Furthermore, investigators and inspectors may note additional risk reduction practices and incorporate

them into the standard process as lessons learned.

Risk Management Suite (RMS)